Lost Foam Casting, also referred to as solid casting, involves creating a cluster of paraffin or foam models that closely resemble the desired final casting. These models are coated with a refractory material, allowed to dry, and then embedded in quartz sand. By applying negative pressure, the sand consolidates around the foam model, which is subsequently melted away when molten metal is poured in, leaving behind an exact replica of the original model.

This innovative casting technique has gained significant traction globally over the last two decades. Initially, in 1967, A. Wittemoser from Germany introduced the concept of "magnetic casting" to prevent sand collapse during the casting process. Later, in 1971, Japan's Nagano pioneered the V-method, or vacuum casting method. Drawing inspiration from these advancements, today’s lost foam casting leverages vacuum techniques to stabilize the sand mold, leading to its rapid adoption worldwide.

One of the standout features of lost foam casting is its ability to produce high-precision castings. This method allows for mold-free and precise formation, eliminating the need for parting surfaces or sand cores. Consequently, the resulting casting is free of flash, burrs, and draft angles, minimizing errors caused by core assembly. Castings produced through this method typically exhibit surface roughness levels of Ra3.2 to 12.5μm and dimensional accuracy within CT7 to CT9. The machining allowance is kept minimal, usually around 1.5 to 2mm, significantly reducing machining costs—by up to 40% to 50% compared to traditional sand casting methods.

Design flexibility is another major advantage of lost foam casting. It offers complete creative freedom for casting designs, allowing highly intricate structures to be cast in one piece without the need for multiple cores. Unlike conventional sand casting, where inaccuracies in core dimensions or positioning can lead to uneven wall thicknesses, lost foam casting ensures uniformity in wall thickness across the casting.

In terms of environmental impact, lost foam casting is notably clean. The molding sand contains no chemical binders, and the foam is harmless at low temperatures. Additionally, over 95% of the used sand can be recycled, making it an eco-friendly option.

Economically, lost foam casting reduces both initial investment and production costs. Since the blank weight of the casting is lighter and the machining allowance is smaller, overall material usage is optimized. However, like any casting process, it has certain limitations. Not all types of castings are suitable for this method, and factors such as batch size, material type, equipment availability, and structural complexity play crucial roles in determining its applicability. For instance, while gray cast iron and non-ferrous alloys are well-suited, low carbon steel and alloy steels require careful preparation to avoid lengthy process adjustments. Additionally, the size of the casting must align with available equipment, and complex structures benefit most from this technique.

Despite these constraints, lost foam casting remains a revolutionary advancement in the foundry industry, offering unparalleled precision and flexibility. Its global adoption continues to grow as manufacturers recognize its potential to enhance efficiency and sustainability.

Long Lifespan: Superior to traditional deep-cycle Flooded/AGM batteries, our products promise extended service life.

High-Temperature Resilience: Outperforming AGM batteries in high temperatures, the EVG series guarantees consistent performance.

Low-Temperature Operation: Excelling where Flooded batteries falter, our batteries deliver reliable power in cold conditions.

Consistent Performance: Enjoy stable ampere-hour capacity and high operating voltage throughout the battery's lifespan.

Maintenance-Free Excellence: Bid farewell to spills and gassing with our nonspillable, maintenance-free design.

Aerial Lifts and Fork Lifts

Golf Carts and Wheelchairs

Floor Sweepers and Electric Vehicles

Mobility and Medical Equipments

Connect with Us:

Share your needs, and our team of battery specialists will be in touch to provide a personalized power solution for you or your company.

Unleash the Power of Innovation with OREMA EVG Series Industrial deep cycle batteries! Catering to both aftermarket and original equipment needs, our GEL traction batteries are a testament to exceptional performance and reliability. Ideal for a range of motive power applications, the OREMA EVG series motive power batteries stands out in the competitive market.

Key Features of OREMA GEL semi-traction battery:

Innovative GEL Technology: Experience the future with our cutting-edge GEL formula, ensuring longevity and efficiency.Long Lifespan: Superior to traditional deep-cycle Flooded/AGM batteries, our products promise extended service life.

High-Temperature Resilience: Outperforming AGM batteries in high temperatures, the EVG series guarantees consistent performance.

Low-Temperature Operation: Excelling where Flooded batteries falter, our batteries deliver reliable power in cold conditions.

Consistent Performance: Enjoy stable ampere-hour capacity and high operating voltage throughout the battery's lifespan.

Maintenance-Free Excellence: Bid farewell to spills and gassing with our nonspillable, maintenance-free design.

Applications of OREMA GEL deep cycle traction battery:

Marine and RVAerial Lifts and Fork Lifts

Golf Carts and Wheelchairs

Floor Sweepers and Electric Vehicles

Mobility and Medical Equipments

Solar and Wind Renewable Energy

Quality Standards:

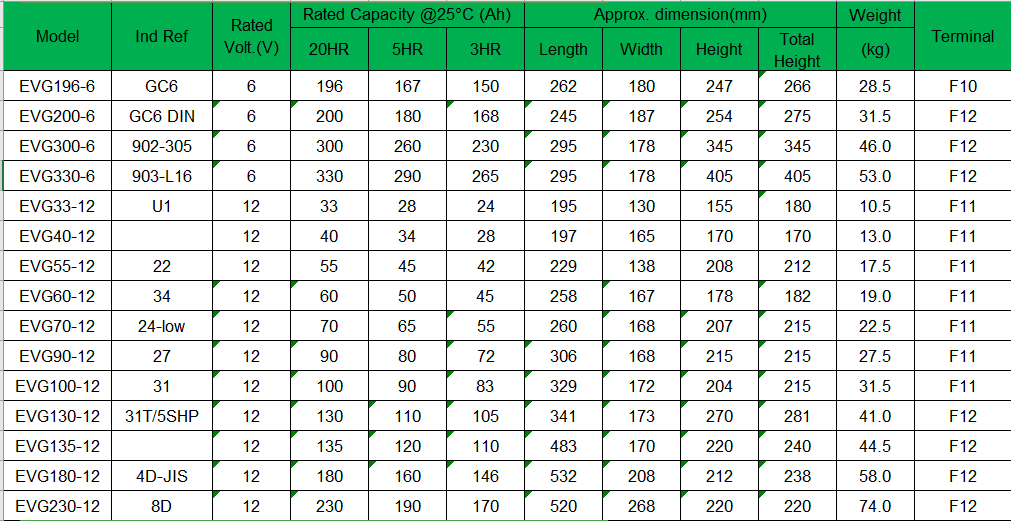

Committed to excellence, the OREMA EVG series complies with IEC, BS, JIS, and EU standards. Our UL and CE certified batteries, produced in ISO45001, ISO9001, and ISO14001 certified facilities, ensure top-notch quality and safety.OREMA EVG Series GEL Motive Power Battery specification sheet:

With a rich heritage in safety and reliability, the OREMA EVG series batteries excel in Partial State of Charge (PSOC) operation and high-temperature conditions. Let us meet your specific power requirements with our customized, reliable power solutions. Trust in our team of battery experts to power your business forward.

Connect with Us:

Share your needs, and our team of battery specialists will be in touch to provide a personalized power solution for you or your company.

GEL deep cycle traction battery,Industrial deep cycle batteries,GEL motive power battery,GEL traction batteries,GEL semi-traction battery

OREMA POWER CO., LTD. , https://www.oremapower.com